As the world faces an ever-increasing demand for energy, there is a growing urgency to shift toward sustainable energy solutions.

Sustainable energy is the key to combating climate change and ensuring a cleaner, greener future for generations to come. One of the critical players in this endeavor is CNC (Computer Numerical Control) machining. This advanced manufacturing technology has a vital role to play in the production of sustainable energy components that are efficient, and eco-friendly.

Importance Of CNC Machining In Sustainable Energy Components

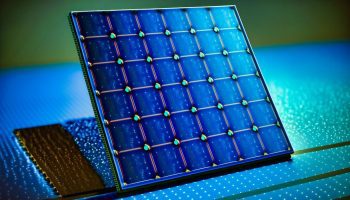

CNC machining has revolutionized the manufacturing industry by automating and streamlining the production process. Machining for green energy industry allows for precision and accuracy that is unmatched by traditional methods, making it an indispensable tool for creating complex and intricate components required for sustainable energy solutions. Whether it’s wind turbines, solar panels, hydroelectric generators, or other green energy systems, CNC machining plays a crucial role in their design and fabrication.

CNC Machining Techniques For Sustainable Energy Components

CNC Milling for Complex Shapes and Structures: CNC milling is a versatile machining technique used to produce intricate shapes and structures. For sustainable energy components, this process is instrumental in manufacturing aerodynamic wind turbine blades, solar panel frames, and other components with intricate geometries. By precisely removing excess material from the workpiece, CNC milling ensures that the finished components are lightweight and optimized for their intended purpose.

- CNC Turning for Cylindrical Components: CNC turning is ideal for producing cylindrical components used in sustainable energy systems, such as shafts, axles, and rotor parts. This process involves rotating the workpiece while a cutting tool shapes it into the desired form. CNC turning ensures high precision and consistency, crucial for the efficient functioning of renewable energy devices.

- CNC Drilling and Boring for Precision Holes: Sustainable energy components often require precise holes for mounting, alignment, and fluid flow. CNC drilling and boring provide accurate hole placement and dimension control, ensuring seamless integration of various parts and optimal performance of the overall system.

- CNC Grinding for Fine Finishing and Tight Tolerances: In some cases, sustainable energy components demand extremely tight tolerances and smooth surface finishes. CNC grinding is the go-to technique for achieving these requirements. This process removes small amounts of material to attain exceptional accuracy and surface quality, enhancing the efficiency and longevity of the energy systems.

Material Selection For Sustainable Energy Components

In this section, we embark on a journey into the realm of Material Selection for Sustainable Energy Components, where cutting-edge CNC services take center stage. From wind turbines and solar panels to electric vehicle components and beyond, the quest for optimal materials has never been more critical.

Considerations for Eco-Friendly and Sustainable Materials

Choosing the right materials for sustainable energy components involves a thorough evaluation of their environmental impact throughout their lifecycle. Manufacturers are increasingly seeking alternatives to traditional materials, such as fossil fuel-derived plastics and metals that contribute significantly to carbon emissions and pollution.

Sustainable materials must be renewable, recyclable, and have low embodied energy. Bio-based materials derived from organic sources like algae, bamboo, or bioplastics offer a renewable alternative to conventional petrochemicals. Recycled metals and composites, produced using discarded materials, reduce the strain on natural resources while minimizing waste.

CNC Machining with Renewable and Recyclable Materials

Computer Numerical Control (CNC) machining plays a crucial role in shaping sustainable energy components with precision and efficiency. By using renewable and recyclable materials in CNC processes, manufacturers can reduce their carbon footprint significantly.

Renewable materials such as sustainable wood, bamboo, or biodegradable plastics can be effectively shaped and machined using CNC techniques. Not only does this enable the creation of intricate and complex designs, but it also promotes a closed-loop manufacturing process by using materials that can be regenerated or disposed of responsibly.

Related: 10 Energy Saving Tips

Enhancing Energy Efficiency through Material Choices

Energy efficiency is a key factor in sustainable energy component design. Choosing materials with high thermal conductivity and low energy loss can optimize the performance of energy systems.

In renewable energy technologies like solar panels and wind turbines, advanced materials like nanomaterial-enhanced composites, which improve energy capture and conversion, are gaining prominence. These materials facilitate higher efficiency and power output, making renewable energy solutions more viable and competitive.

Conclusion

As the world addresses the challenges of climate change and environmental degradation, sustainable energy solutions have become more critical than ever. CNC machining emerges as a valuable ally in the machining for the green energy industry, enabling the production of complex, efficient, and eco-friendly components.

Through CNC milling, turning, drilling, and grinding, manufacturers can produce intricate structures that optimize the performance of wind turbines, solar panels, hydroelectric generators, and other sustainable energy systems. Moreover, CNC machining allows for the use of renewable and recyclable materials, promoting environmental responsibility in the production process.

Read Also:

- Going Green: The Benefits of Installing Solar Panels on Your Home

- The Essential Solar Panel Installation Guide For Homeowners

- 9 Reasons To Go Green And Switch To Solar Energy