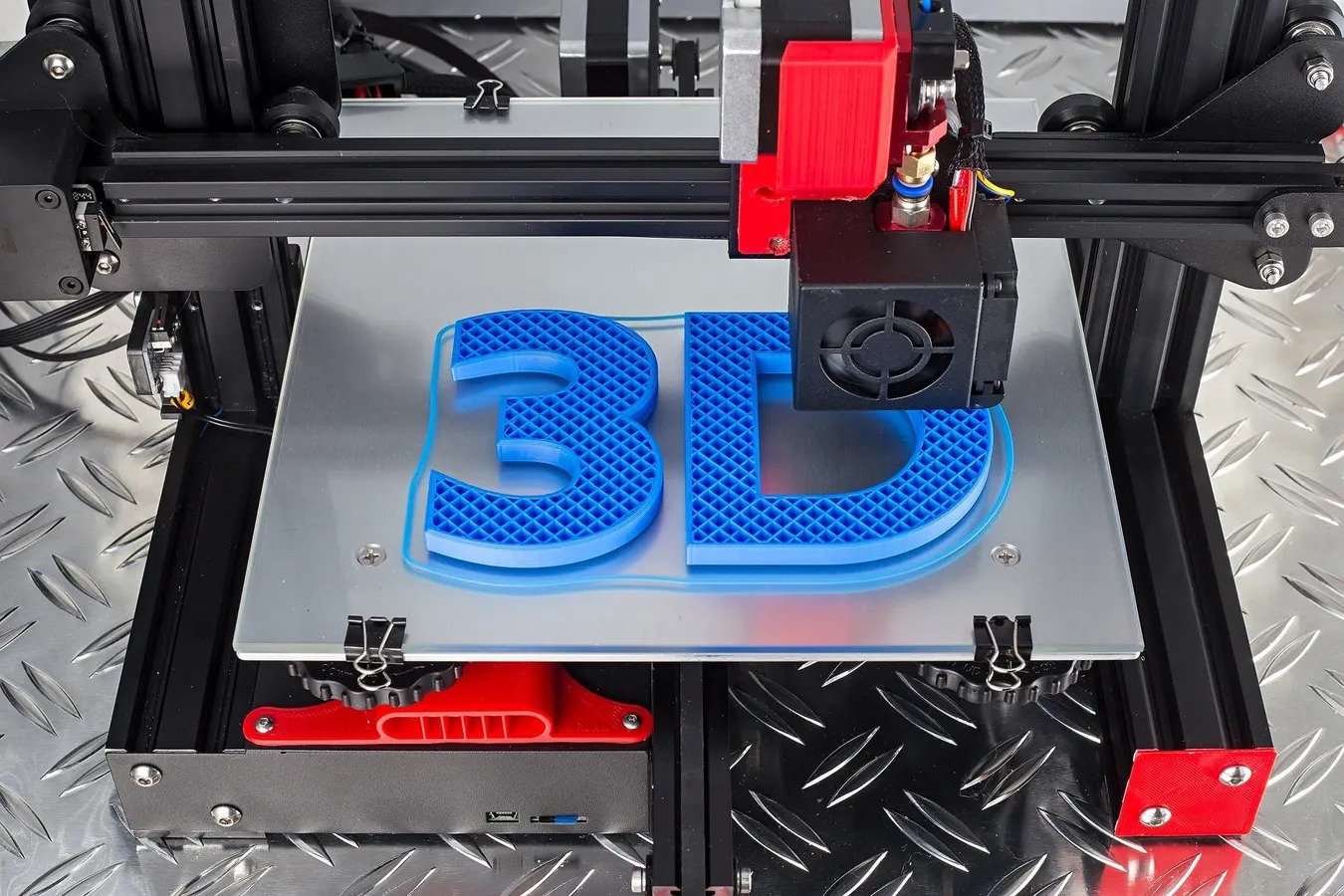

3D printers have revolutionized the way traditional manufacturing processes are carried out. These machines offer a wide range of solutions for various industries.

In addition, used 3D printers are now becoming increasingly popular. This is because of their cost-effective benefits and advanced features as well. Used 3D printers are reshaping the manufacturing industry as well.

If you want to learn how used 3D printers are changing the game for traditional manufacturing, this article is for you!

Read further!

Cost-Effective Prototyping

Rapid prototyping has been a crucial aspect of manufacturing for decades. But, it often came at a high cost. The cost of prototyping has been reduced. This comes along with the introduction of pre-owned 3d printers.

These printers allow businesses to experiment with designs and models. This can be done without investing in expensive equipment or materials. This not only speeds up the development process but also improves product quality.

Moreover, used 3D printers offer customizable options that cater to specific production needs. This means that businesses can tailor their prototypes according to their exact requirements. This helps in ensuring efficient and effective product development.

Customization and Complexity

Traditional manufacturing processes often require a large team to oversee production. This was necessary to ensure quality control and prevent human error. Used 3d printing equipment has greatly reduced the need for extensive manual labor.

These machines can produce complex designs with ease. It comes along with advanced printing techniques. This reduces the risk of human error and also speeds up the production process.

Furthermore, used 3D printers allow for customization and personalization of products. This is especially beneficial for industries such as healthcare. This is mostly where personalized medical devices can improve patient care.

Reduced Lead Times

Traditional manufacturing processes can often take weeks or even months to produce a single product. This is due to the time-consuming steps involved. This includes creating molds and tooling.

However, having used 3D printers eliminates the need for these steps. This results in significantly reduced lead times. It allows businesses to quickly respond to market demands and stay ahead of their competition.

Plus, it saves time and resources in the production process.

Sustainable Manufacturing

Used 3D printers, along with the best 3d scanners, also offer a more sustainable solution for manufacturing. These machines can reduce material waste and energy consumption. This can be possible by utilizing additive manufacturing.

They also have the potential to enable localized production. This helps in reducing the carbon footprint associated with transportation and logistics. It also makes used 3D printers an attractive option for businesses. This is especially true for those looking to minimize their environmental impact.

Learn How Used 3D Printers Revolutionize Manufacturing

The rise of used 3D printers has brought about numerous benefits. These machines have reshaped the industry in more ways than one.

Furthermore, they also offer solutions for supply chain resilience. This makes them a valuable asset for businesses. This is especially true for those looking to stay competitive in today’s market.

It is then high time businesses consider investing in these machines. So, what are you waiting for? Embrace the future of manufacturing with used 3D printers.

Should you wish to read more, visit our blog. We’ve got more!